As a research and development service provider for combustion engines, FVTR has specialized in particular in the field of alternative fuels and agricultural machines. During several projects we have built up a deep understanding of the several interactions between fuels and lubricants as well as fuels and exhaust aftertreatment components.

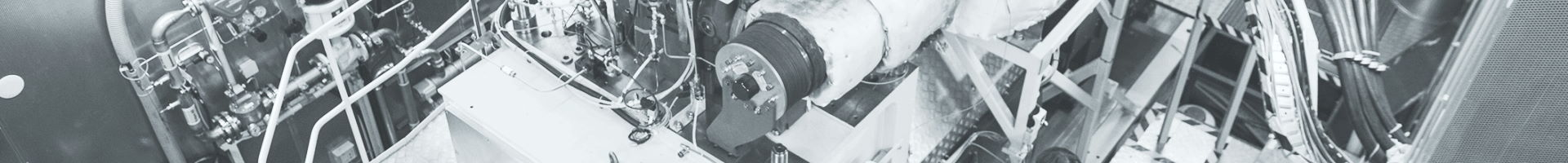

Altogether, five test benches in the light and medium engine scale are currently available for your project ideas.

Key Benefits for Your Project

- Modern engine test benches

- Expert knowledge in test bench built ups

- Skilled and flexible technical and scientific staff

- Tailor made investigation of bio fuel performance

- State of the art exhaust gas analyzation systems

- Large fuel infrastructure including special fuels and gas mixing facility

Are you interested in further information? Feel free to contact our friendly experts. Together we will find a solution for your challenges.

Detailed Information

Challenges in Light & Medium Engine Development

In our opinion, the high efficient combustion engine is an elementary key element on the way to an energy revolution in the mobile transport sector. To reach the CO2 reduction goals of the EU and the Paris climate agreement even further development efforts will be needed. Looking to the long-term future of traditional engines, we think that renewable and climate neutral fuels will still be burned in internal combustion engines, because of their benefits in energy density, infrastructure, availability and the efficiency of the engines itself. Against this challenging and fascinating background, we would be pleased to accompany you in your devlopment projects.Fuel Infrastructure

In addition to conventional liquid fuels, our fuel infrastructure also offers the possibility of using bio-fuels of various qualities and special fuels at the engines:- Gasoline according to DIN EN228 and gasoline blends

- Diesel according to DIN EN590 and diesel blends

- Bio Diesel: B30, B100, FAME

- Special fuels: methanol, ethanol, HVO, OME, DME

- Natural gas at different pressure levels: 20, 250, 600 bar

- Gas mixing facility: addition of CO2 and C3H8 to the natural gas

Test Beds and Equipment

- Test bed dynos by Schneider/Elin up to 220 kW

- Test bench automation by AVL Puma

- Fuel conditioning and Measurement by AVL solutions

- INCA tool boxes for application work

- AVL ISAC 400 driving simulator for automatic and endurance testing

- State of the art indication systems by AVL/Kistler

- Tailor made and open engine control unit architecture for single cylinder research engines

Exhaust Gas Analyzation

For the investigation of emission-relevant components or operating strategies, modern exhaust gas analyzing systems are available:- Certification-relevant measuring systems (FID and CLD)for NOx, CO2, HCs

- FTIRs for the measurement of up to 24 special gases like N2O, NH3 and SO2

- Determination of FSN with smokemeter

- Mobile particle measuring station: particle concentration, number and size

Our Development Services

- Combustion process development

- Development of gas powered medium duty engines

- Component testing: sensors, injection components, turbochargers, …

- Fuel and lubricant tests

- Development of operating strategies for light and medium duty engines

- Testing of DOCs, DPFs, SCRs under usage of bio-fuels

- Investigation of the loading behavior of catalysts and filters

- Synthetic aging of exhaust aftertreatment components in high temperature ovens

- Application of special measurement techniques like surface thermocouples at pistons or conrods

- Investigation of injection and mixture formation processes at own and specialized injection test benches

- Analysis of customer samples in the fuels and lubricantslaboratory

- Simulation of the combustion process by our own experienced and well-equipped CFD-team