The visualization and analysis of fuel sprays and gas jets allows the systematic investigation of mixture formation and combustion processes. We analyze atomization, evaporation and combustion phenomena using one of the worlds largest high pressure - high temperature - spray chambers and state of the art measurement equipment.

Key Benefits for Your Product

- Analysis of diesel sprays at gas temperatures and densities just like in the engine

- Measurement equipment specialized for large engine applications

- Quantitative information about mixture generation for your combustion process

- Choose the right injection system based on fact

- Parameterize and validate spray and combustion models

- Support for single cylinder research projects

- Quantitative information about the eff ects of nozzle wear and fuel deposits

Are you interested in further information? Feel free to contact our friendly experts. Together we will find a solution for your challenges.

Detailed Information

Large Engine Injection Systems

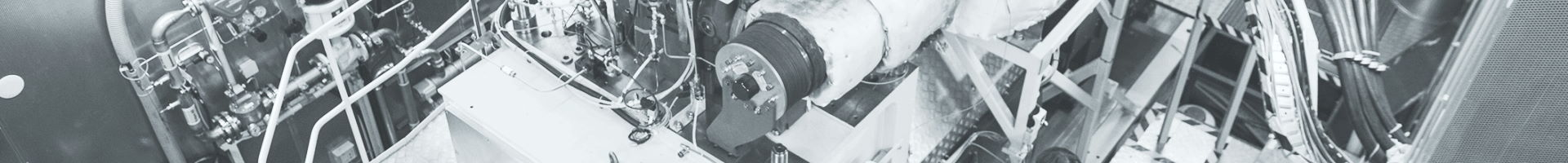

Demands on large engine injection systems are rising as technologies like multiple injections are being adopted and new technologies like dual-fuel engines are being developed. Efficient testing and optimization of injectors and nozzles regarding their suitability for these new technologies involves the analysis of mixture formation and combustion.Spray Chamber

By conditioning of the test bench to 300°C we ensure a uniform temperature distribution within the measurement volume. Compressed air or nitrogen is heated in continuous-flow heaters to up to 900 °C. The spray chamber is then continuously scavenged in order to flush fuel vapor and combustion gases and to sustain the homogenous temperature distribution. The diesel injector or other test object is passively and actively cooled because fuel throughput is much lower on the test bench compared to the engine. Depending on the task at hand, we operate the injector transiently to inject smallest quantities or generate steady state conditions. Our equipment is specialized for large engine injectors, but can very well be used for heavy duty and non-engine applications.Measurement and analysis procedure

We are able to capture macroscopic properties of the evaporating spray or the gaseous jet using well established planar measurement techniques like schlieren or multicolor pyrometry. Videos are captured using state-of-the-art monochrome and color high speed cameras. In order to process the data for the spray analysis, we use algorithms that are developed and adapted by our experts to solve the challenges of each specific measurement task.Technical Data

- Measurement of liquid and gaseous spray and jets

- Common rail pressures up to 2200 bar

- Gas temperatures up to 900 K

- Gas pressures up to 150 bar

- Window diameter 300 mm

- Suitable for engine bores of approx. 100 - 400 mm

- Fuels: diesel fuel, heavy fuel oil, crude oil, renewable fuels and e-fuels

- Gases: helium (substitute for hydrogen), neon (substitute for methane)

Measurement System

- High speed cameras for detailed tracking of individual spray events

- Schlieren-scatter light optics for simultaneous visualization of liquid and gaseous phase of an evaporating spray

- Color high speed camera for analysis of burning sprays regarding temperature and soot distribution

- PDI – Phase doppler interferometer for measurements of droplet velocity and size distribution of light sprays

- Soot luminescence and chemiluminescence for analyzing ignition cites and flame lift off lengths