Ammonia is currently a widely discussed fuel. The chemical compound with the molecular formula NH3 consists of nitrogen and hydrogen, and this is exactly its advantage: it contains no carbon and is therefore CO2-neutral. As part of the BMWK-funded project "Development of Simulation Tools for Future Maritime Ammonia Combustion Engines", short German title "AmmoniakMotor", basic principles for the internal engine energy conversion of ammonia are being determined. This is realized by coupled experimental and simulation-based investigations. The focus of the project is on inland shipping: Retro-fitting the existing fleet is a realistic and cost-effective solution to achieve the decarbonization targets of the energy transition by 2050.

In addition to FVTR GmbH as project coordinator, the Chair of Piston Engines and Internal Combustion Engines (LKV) at the University of Rostock and LOGE Deutschland GmbH are involved in the project. The aim is to develop simulation models to describe a dual-fuel combustion process in which ammonia is ignited via a small amount of diesel. The simulations will help to understand the internal engine ammonia combustion and to determine optimal engine operating strategies.

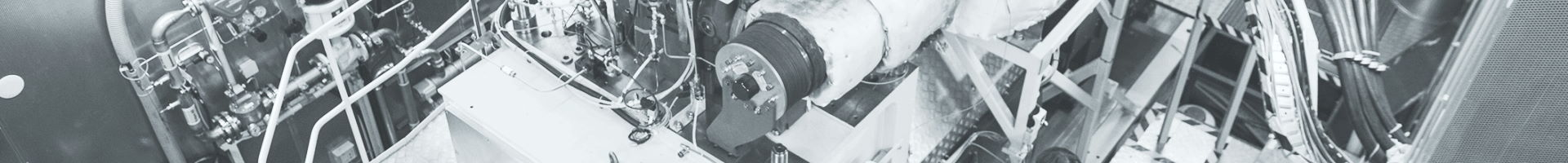

Experimental investigations are being carried out at LKV on a research engine that is being converted for this purpose to dual operation with ammonia and diesel (retro fit). With a bore of 110 mm, this is in the order of magnitude of inland marine engines. FVTR GmbH is creating a digital twin of this engine and can thus assist in determining suitable operating points. The ammonia combustion model required for this is supplied by the third project partner, LOGE Deutschland GmbH. The aim of the project is to develop a simulation tool which enables engine manufacturers and retrofitters to optimally design an ammonia engine already on the computer.

For detailed information, feel free to contact Dr. Martin Theile.