Exhaust gas condensation is a highly topical issue in engine and automotive industry. Engine developing and manufacturing companies often face problems with fouling and corrosive exhaust systems, leading to costly warranty cases that reduce overall company revenue. The FVTR company offers a wide range of industrial research concerning exhaust gas condensation. We support you with modeling, simulation and experimental research to address your technical challenges and optimize your systems as well as production processes.

Key Benefits for Your Project

- Cooperation with the leading experts in the field of condensation modeling

- Custom experimental design and realisation

- Scientific based investigation and model development

- Time and cost efficient project realization

- Tailor-made consulting and detailed reports to support you in your decision making

Are you interested in further information? Feel free to contact our friendly experts. Together we will find a solution for your challenges.

Exhaust Gas Condensation: Challenges and Opportunities

Exhaust gas condensation plays a major role in many engine related applications. On the one hand this physical effect gives rise to large potentials like onboard water collection from the exhaust gas stream, on the other hand critical challenges such as corrosion, fouling and blocking of coolers occur. This condensation is attributed to the inherent exhaust gas composition containing water, hydrocarbons and several acidic components. A thorough understanding of the involved processes and the capability of precisely describing these processes is the key to design and optimization of your engine components and processes.

Our Unique Condensation Models and Experimental Equipment

Recently our experts developed models describing the interrelated vapor pressure of the three components water, sulfuric acid and nitric acid. Together with novel condensation models in 1D and 3D contexts we can precisely predict condensate mass flows and condensate composition of your systems.

The basis for this thorough simulation work is our state of the art equipment:

- Engine test beds for exhaust gas generation

- Synthetic gas test benches for detailed investigations on gas composition impacts

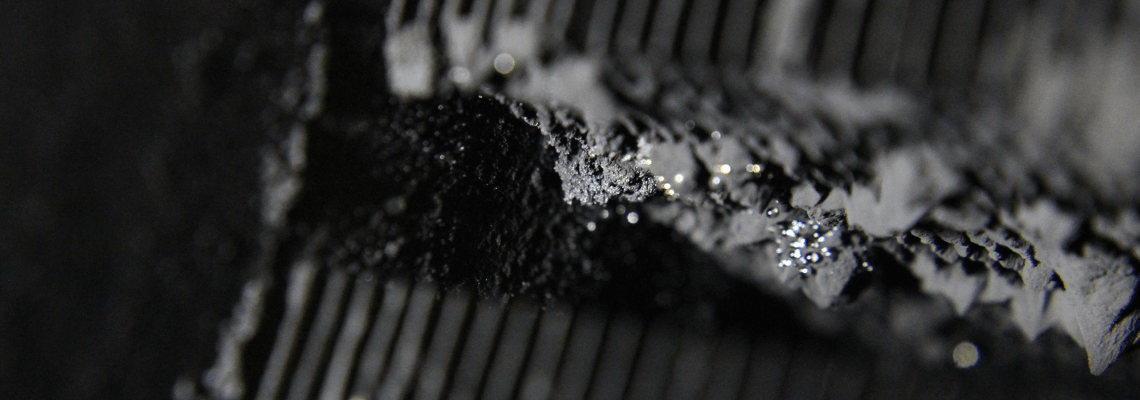

- Chemical lab for analyzing condensates and deposits

- Several successful projects with well-known engine manufacturers and Tier I suppliers show the benefits our approach can offer to your company as well.

Modeling & Simulation

0D/1D Modeling

- Prediction of exhaust gas dew point and chemical composition of condensates depending on fuel and operating conditions

- Simulation of heat transfer and condensate mass flow for basic geometries

3D Modeling

- Simulation of heat and mass transfer for complex geometries

- Design optimization with regard to flow and condensation

Experimental Research

Engine Test Bench

- Evaluation of exhaust gas related engine structures

- Analysis of fouling-induced phenomena in heat transfer and life time

- Condensate collection and chemical analysis

- Microscopic analysis of fouling layers

- Short and long duration tests

Synthesis Gas/Vapor Test Bench

- Variable composition of synthetic gas allows for simulating behavior of different types of exhaust (fuel, engine operation)

- Testing of cooled exhaust gas components regarding condensation and/or chemical resistance