- Successful commissioning of hydrogen infrastructure for development test benches -

After a planning and construction phase of about one year, the engine operation of a 1-cylinder research engine for the development of hydrogen combustion processes in the commercial vehicle sector started recently. With this, FVTR GmbH is putting the first of two planned engine test benches into operation.

Hydrogen as a fuel is currently being discussed as a CO2-free alternative for a number of powertrain applications. In order to be available as a partner to engine developers, FVTR GmbH has expanded its own fuel infrastructure and can now offer research and development services for hydrogen combustion process development in the commercial vehicle sector.

Hydrogen trailer in the technical yard

Hydrogen trailer in the technical yard

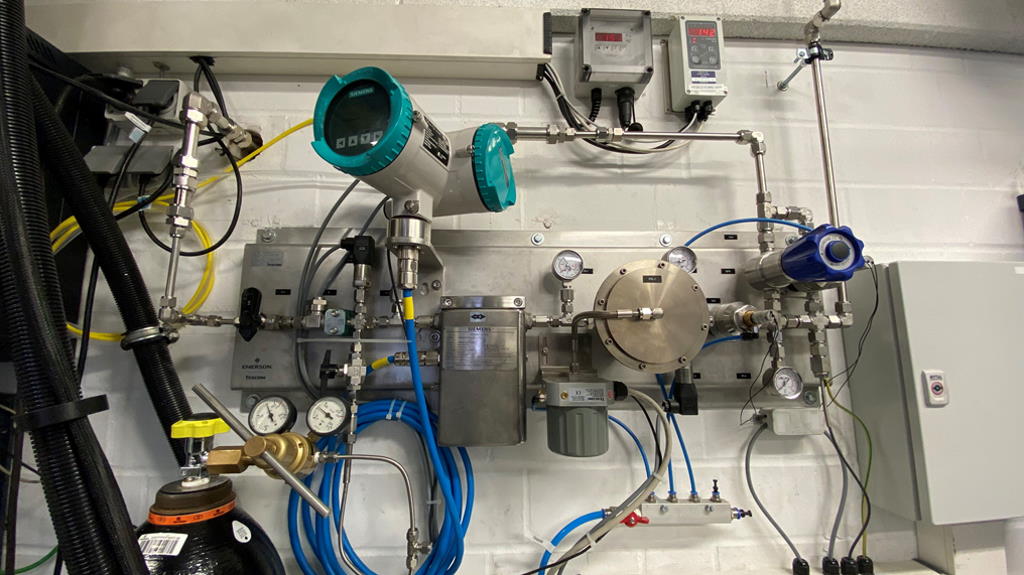

The hydrogen itself can be fed into the blending station by means of a transfer station, either from cylinder bundles or from a commerical trailer. This opens up the possibility of using green or conventional hydrogen. Depending on the application, this pressure level can be in the medium-pressure range (up to 55 bar, current stage) or the high-pressure range (up to 450 bar by means of a pressure intensifier, future stage planned for 2022). The engine test bench was equipped with extensive safety and monitoring technology to meet the high demands of hydrogen use. The test bench is currently equipped for engine tests with effective outputs up to 200 kW. An increase in output can be technically implemented if required. Currently, a 1-cylinder unit with 55 kW power is installed.

Single-cylinder research engine with hydrogen injection

In initial tests, CO2-free engine operation with hydrogen under full load has already been demonstrated. An electric pressure control system allows flexible tests under transient hydrogen pressure conditions with high control quality. Component damage due to knocking and backfire effects can also be avoided by process monitoring based on an online indication system at the test bench. The engine test bench is thus "H2-ready" for a wide range of research tasks up to the limits of heavy-duty combustion process development.

Hydrogen pressure regulation in the test bench

Hydrogen pressure regulation in the test bench

"Technology openness for future powertrains in the mobile on-road and off-road, medium- and heavy-duty sectors as well as for marine engines make hydrogen indispensable as an energy carrier and fuel. In addition to hydrogen, the use of other PtX fuels such as e-diesel must also be evaluated on an application-specific basis. All studies indicate that not one, but many technologies will make it into series use, depending on the requirements," says FVTR CEO Martin Reißig. "We are ideally positioned for this with our fuel infrastructure. In addition to the classic fuels, we can also offer engine tests with the currently discussed future fuels such as methanol, ammonia and hydrogen."

Martin Drescher and Martin Reißig, FVTR GmbH, Hartmut Siewert, Westfalen AG, Prof. Karsten Müller and Prof. Bert Buchholz, University of Rostock (from left)

FVTR GmbH is already involved in several projects and scientific consortia on the topics of ammonia and hydrogen in motor applications. With the help of the new hydrogen infrastructure, FVTR GmbH can now offer its know-how in this field to industrial customers.

FVTR (Forschungszentrum für Verbrennungsmotoren und Thermodynamik Rostock) GmbH is an independent research and engineering service provider in the field of engine development and thermodynamic energy conversion processes. With our know-how, we help our customers to operate more efficient engines and plants, thus protecting the environment and natural resources. We have been in existence since 2007 and employ 28 people at our Rostock site, from mechanics to PhD engineers.